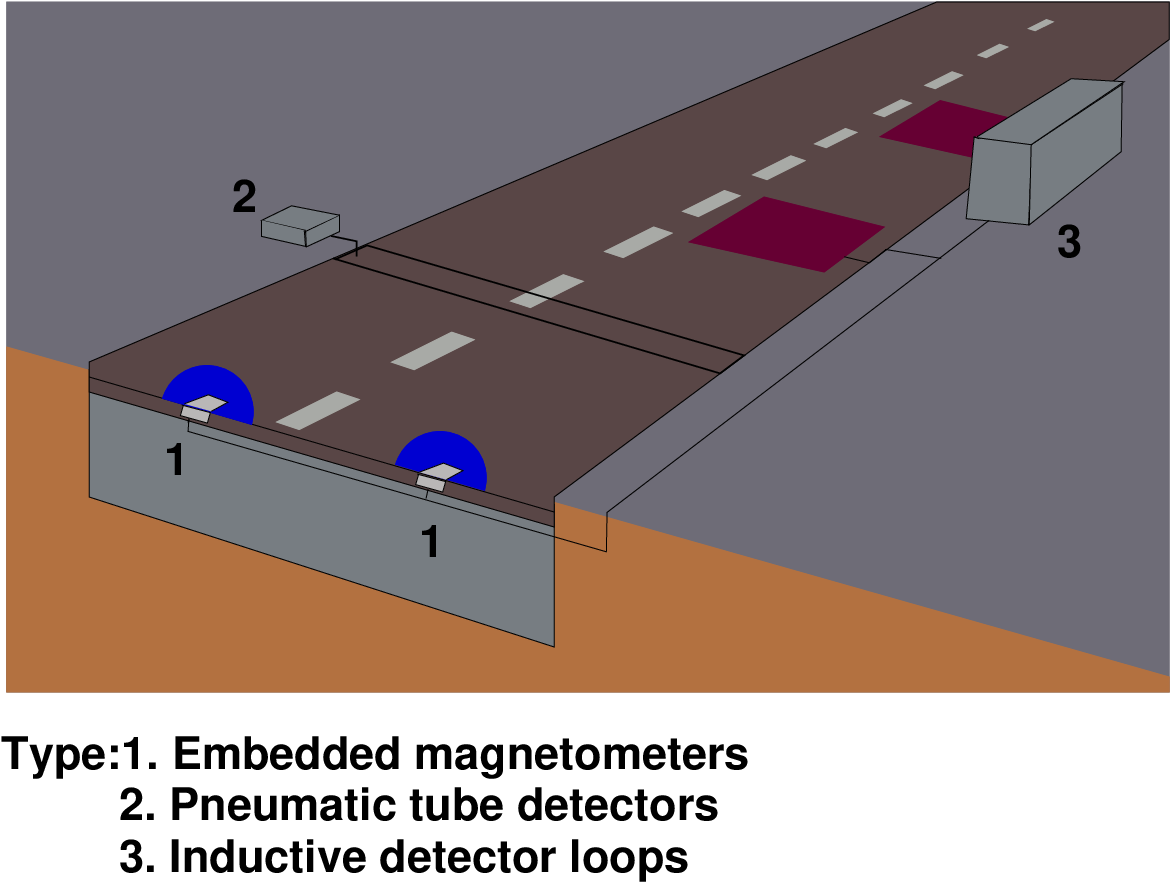

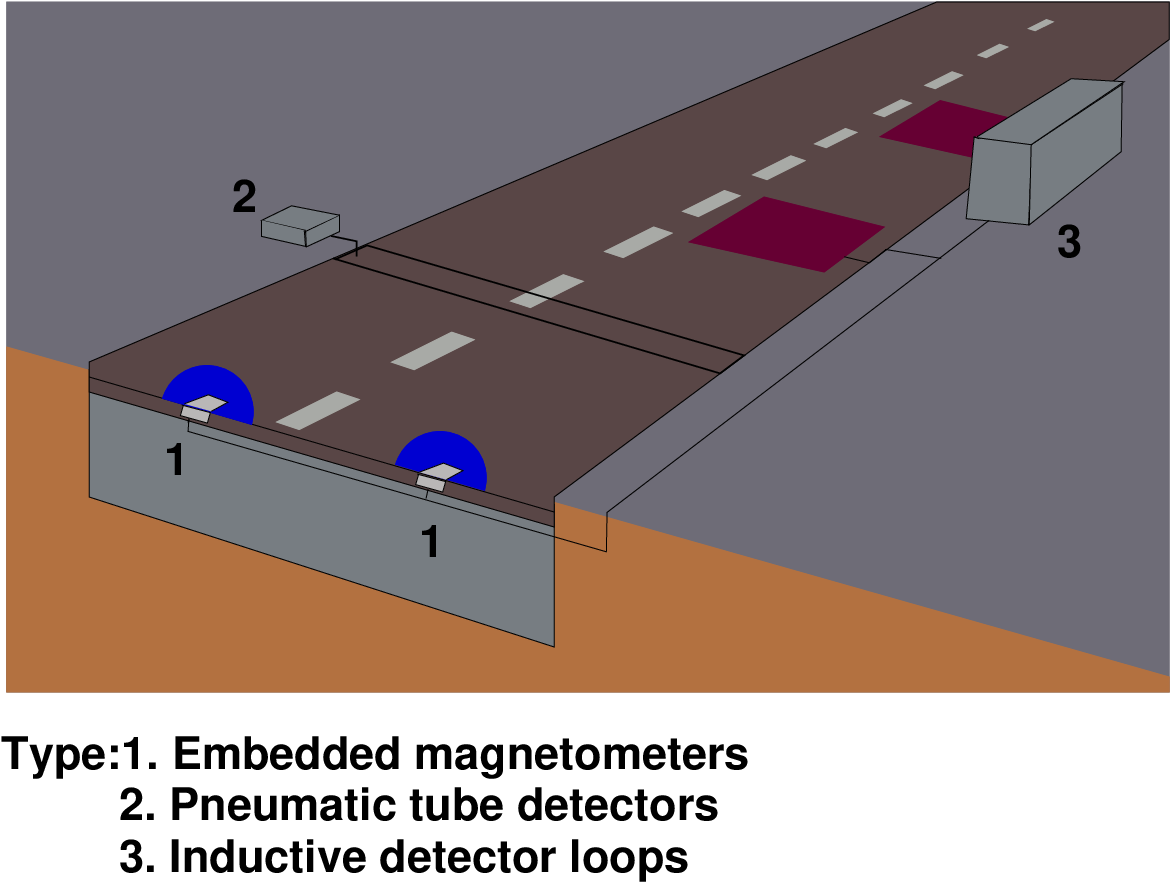

Typical examples of intrusive technologies, their sensor types and installation locations are

shown in Fig. 1. The first types of units (Fig. 1, Type 1) are passive magnetic or

magneto-meter sensors that are either permanently mounted within holes in the road, or

affixed to the road surface in some fashion. The unit communicates to a nearby base station

processing unit using either wires buried in the road, or wireless communications.

The sensor has a circular or elliptically offset zone of detection (i.e., the blue area).

The second types of units (Fig. 1, Type 2) use pneumatic tubes that are stretched across

the carriageway and affixed at the kerb side at both ends. Such systems are only be deployed

on a temporary basis, due to the fragile nature of tubes, which are easily damaged or torn up

by heavy or fast moving vehicles.

The third type (Fig. 1, Type 3) are inductive detector loops (IDL), consisting of coated wire

coils buried in grooves cut in the road surface, sealed over with bituminous filler. A cable

buried with the loop sends data to a roadside processing unit. The zone of detection for

inductive loop sensors depends on the cut shape of the loop slots. The zones depending on

the overall sensitivity of system not correspond precisely to the slot dimensions. IDLs

are a cheap and mature technology. They are installed on both major roads and

within urban areas, forming the backbone detector network for most traffic control

systems.

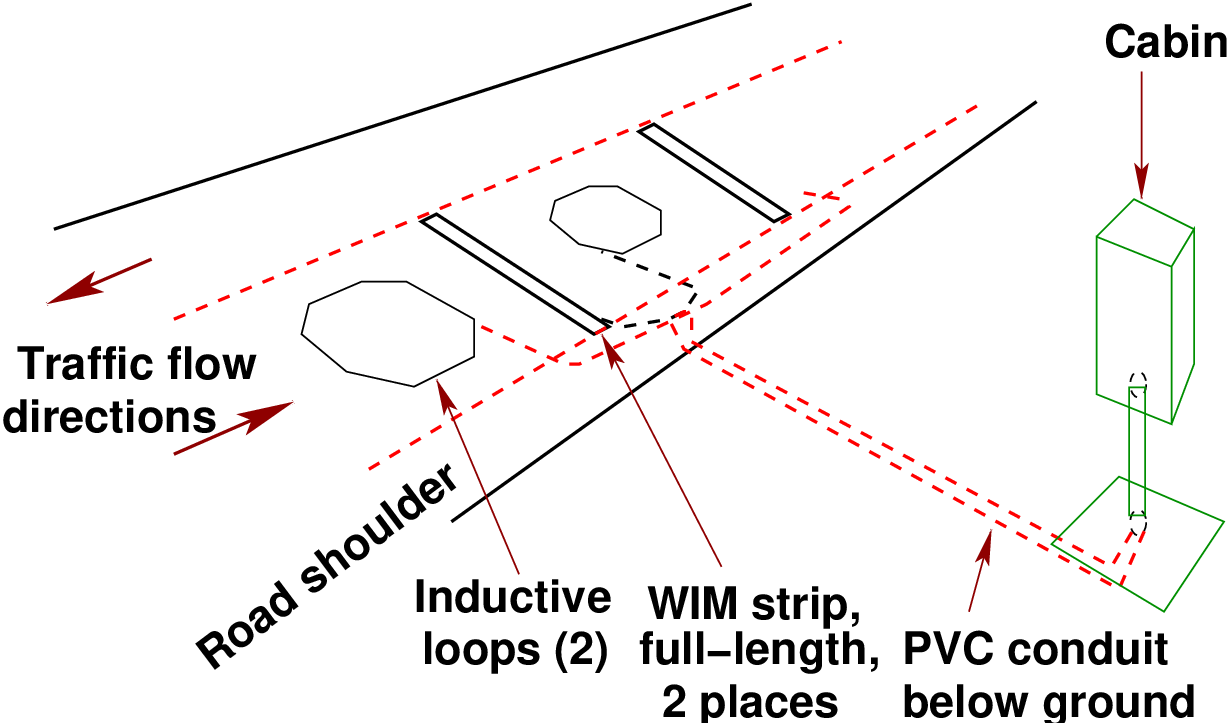

The fourth type of intrusive system is Weigh-In-Motion (WIM) shown in Fig. 2, detectors that

consist of a piezoelectric sensor (e.g. ‘bending-plate’ or fiber-optic) system laid in a channel

across the road. These systems are relatively rare and are used in specific locations

for enforcement or access control. They are usually coupled with other systems,

either intrusive or non-intrusive, to provide additional cross-checks on collected data.

Pneumatic road tube sensors send a burst of air pressure along a rubber tube when a

vehicles tire passes over the tube. The pulse of air pressure closes an air switch, producing

an electrical signal that is transmitted to a counter or analysis software. The pneumatic road

tube sensor is portable, using lead-acid, gel, or other rechargeable batteries as a power

source. The road tube is installed perpendicular to the traffic flow direction and is

commonly used for short-term traffic counting, vehicle classification by axle count

and spacing. Some data to calculate vehicle gaps, intersection stop delay, stop

sign delay, and saturation flow rate, spot speed as a function of vehicle class, and

travel time when the counter is utilized in conjunction with a vehicle transmission

sensor.

Advantages

Disadvantages

Oscillating electrical signal is applied to the loop. The metal content of a moving

vehicle chassis changes the electrical properties of circuit. Changes are detected at a

roadside unit, triggering a vehicle event. A single loop system collects flow and

occupancy. The speed can be calculated by the assumptions that are made for the mean

length of vehicles. Two-loop systems collect flow, occupancy, vehicle length, and

speed.

Advantages

Disadvantages

A typical single loop system is shown in Fig. 3. The system consists of three components: a detector oscillator, a lead-in cable and a loop embedded in the pavement. The size and shape of loops largely depend on the specific application. The most common loop size is 1.83 m by 1.83 m and shape is hexagonal as single turn or two or three turns as shown in Fig. 3. When a vehicle stops or passes over the loop, the inductance of the loop is decreased.The decreased inductance then increases the oscillation frequency and causes the electronics unit to send a pulse to controller, indicating the presence or passage of a vehicle. Single loop detectors output predicts occupancy and traffic count data within specific time intervals like 20 sec, 30 sec.

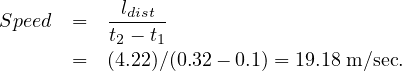

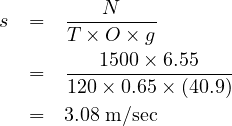

Dual-loop detectors are also called speed traps, T loops, or double loop detectors. In a dual-loop system, two consecutive single inductance loops, called “M loop” and “S loop”, are embedded a few distance apart as shown in Fig. 4. With such a design, when one of them detects a vehicle, timer is automatically started in the dual-loop system and runs until the same vehicle is detected by other loop.Thus, in addition to outputs of vehicle count and occupancy data, individual vehicle speeds can be trapped through the dividend of the distance between those two single loops ldist by the elapsed time. Speed trap is defined as the measurement of the time that a vehicle requires to travel between two detection points. Spot speed is measured by following Eqn. 1.

| (1) |

where,

ldist = Distance between two loops in meters

t1 = Vehicle entry time at first loop in sec

t2 = Vehicle entry time at second loop in sec

Dual-loop detectors can also be used to measure vehicle lengths with extra data

extracted from controllers’ records. The length of vehicle is measured by following

Eqn. 2:

| (2) |

where,

Lvehicle = Length of vehicle in meters.

oti = on-time for loop detector i; Speed in m/sec

Example-1

If the vehicle entering the freeway in loop M at time 8:32:22:00 am and leaving loop N at time

8:32:22:15 am, the distance between two loops will be 3.66 m. Find the spot speed of the

vehicle. Also find the length of the vehicle if time occupancy for M - loop is 0.25sec and 0.29

for N - loop.

Solution:

Step 1 Spot Speed calculated from the equation 1, where given that the distance between

two loops are 3.66m and entry, exit times are 8:32:22:00 and 8:32:22:15 substitute in Eqn. 1.

SpotSpeed = (3.66)∕(15 - 0)∕100 = 24.4 m∕sec.

Step 2 The vehicle length can obtained by the spot speed of the vehicle, so substitute the

occupancy times at exit and entry in the Eqn. 2.

| (3) |

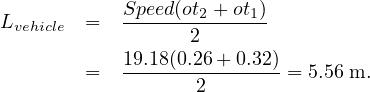

Fig. 5 shows a two-lane unidirectional roadway segment with single loop detectors installed.Assume that the detection zone length is ld and is equal to the detector length, the length of the vehicle is lv, the speed of the vehicle is S, then the actual time (the time period that the vehicle is over the detector) can be calculated by:

| (4) |

where,

S = Spot speed in m/sec

EV L =vehicle length lv + detector length ld

to = Occupancy time

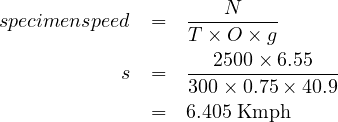

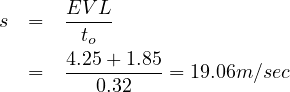

There are many algorithms for estimating speed by single loop. The most common method is based on the relationship between fundamental traffic variables. It uses a constant or a function to convert loop occupancy into density. The variables include inductive loop length, average vehicle length, occupancy, and traffic volume.For the given number of vehicle and duration of the observed data the specimen speed can find by following Eqn. 5 is shown below.

| (5) |

where,

S = Space mean speed in m/sec

N = Number of vehicles in the observed interval

T = Observation interval in sec

O = occupancy time

g = speed correction factor; (based upon assumed vehicle length, detector configuration, and

traffic conditions) Most of the algorithms followed as (40.9/6.55) for average vehicle length

6.55m.

Example-2

The length of vehicle is 4 m and the length of loop detector zone is 1.83 m. The time

occupancy in the loop is 0.3 sec, find the spot speed of the vehicle?

Solution:

From the given data the average vehicle length is 4 m and the length of loop detector zone is

1.833 m, the time occupancy in loop is 0.3 sec substitute in Eqn. 1.

Loop detectors detect the frequency changes from zero to different level, the inductance

changes are computed by change in frequency. The change in inductance due to the

presence of vehicle is recorded at a small time interval. The waveform obtained by

plotting the sampled inductance changes is referred to as the vehicle inductive

waveform or inductance signature.This waveform depends on number of vehicle

parameters such as vehicle length, speed, and metal surface of the vehicle. Fig. 6

shows an inductive waveform of a typical passenger car.Horizontal axis records data

points at 10 milliseconds interval. This is the common shape of inductance waveform

that has one peak in the middle with monotonic decrease in both sides. Vehicle

signatures are functions of vehicle speed and vehicle type, so many features can be

derived from the vehicle signatures directly or indirectly. Volume and occupancy are

directly derived from processing raw vehicle signatures whereas speed is estimated

based on the vehicle signature feature vectors. Vehicle length is obtained based on

vehicle speed. By combining vehicle length with existing vehicle signature features,

vehicle classification can be measured. It is easy to observe signature differences

arising from the vehicle speed. Duration or occupancy has an inverse proportional

relationship with speed while slew rate shows a proportional correspondence with speed.

A series of vehicle signature acquired by the Inductive Loop Detectors located at upstream and downstream of a freeway and different distance measures to find the re identification accuracy level. Double-axle trucks produce a double picked vehicle signature when the resolution of detector is adequate. Thus, it can be easily used for vehicle-type identification purposes.

Magneto-meters monitor for fluctuations in the relative strength of the Earth’s magnetic field,

which is changed by the presence of a moving metal object i.e., a vehicle. A single passive

magnetic system collects flow and occupancy. Two magneto-meter systems collect flow,

occupancy, vehicle length, and speed.

Two types of magnetic field sensors are used for traffic flow parameter measurement. The first

type, the two-axis flux-gate magneto-meter, detects changes in vertical and horizontal

components of the Earth s magnetic field produced by a ferrous metal vehicle. The two-axis

flux-gate magneto-meter contains a primary winding and two secondary sense winding on a

coil surrounding high permeability soft magnetic material core. The second type of

magnetic field sensor is the magnetic detector, more properly referred to as an

induction or search coil magneto-meter shown in Fig. 7. It detects the vehicle signature

by measuring the change in the magnetic lines of flux caused by the change in

field values produced by a moving ferrous metal vehicle. These devices contain a

single coil winding around a permeable magnetic material rod core. However, most

magnetic detectors cannot detect stopped vehicles, since they require a vehicle

to be moving or otherwise changing its signature characteristics with respect to

time.

Advantages

Disadvantages

Bending plate WIM systems utilize plates with strain gauges bonded to the underside. The

system records the strain measured by strain gauges and calculates the dynamic load. Static

load is estimated using the measured dynamic load and calibration parameters. Calibration

parameters account for factors, such as vehicle speed and pavement or suspension dynamics

that influence estimates of the static weight. The accuracy of bending plate WIM

systems can be expressed as a function of the vehicle speed traversed over the plates,

assuming the system is installed in a sound road structure and subject to normal traffic

conditions.

Advantages

Bending plate WIM systems is used for traffic data collection as well as for weight

enforcement purposes. The accuracy of these systems is higher than piezoelectric systems

and their cost is lower than load cell systems. Bending plate WIM systems do not require

complete replacement of the sensor.

Disadvantages

Bending plate WIM systems are not as accurate as load cell systems and are considerably

more expensive than piezoelectric systems.

Piezoelectric WIM systems contain one or more piezoelectric sensors that detect a change in

voltage caused by pressure exerted on the sensor by an axle and thereby measure the axle s

weight. As a vehicle passes over the piezoelectric sensor, the system records the sensor

output voltage and calculates the dynamic load. With bending plate systems, the

dynamic load provides an estimate of static load when the WIM system is properly

calibrated.

The typical piezoelectric WIM system consists of at least one piezoelectric sensor and two

ILDs. The piezoelectric sensor is placed in the travel lane perpendicular to the travel

direction. The inductive loops are placed upstream and downstream of the piezoelectric

sensor. The upstream loop detects vehicles and alerts the system to an approaching

vehicle. The downstream loop provides data to determine vehicle speed and axle

spacing based on the time it takes the vehicle to traverse the distance between the

loops. Fig. 8 shows a full-lane width piezoelectric WIM system installation. In this

example, two piezoelectric sensors are utilized on either side of the downstream

loop.

Advantages

Typical piezoelectric WIM systems are among the least expensive systems in use today in

terms of initial capital costs and life cycle maintenance costs. Piezoelectric WIM systems can

be used at higher speed ranges (16 to 112 kmph) than other WIM systems. Piezoelectric WIM

systems can be used to monitor up to four lanes.

Disadvantages

Typical piezoelectric systems are less accurate than load cell and bending plate WIM

systems. Piezoelectric sensors for WIM systems must be replaced at least once every 3

years.

Problems:

Each detector technology and particular device has its own limitations and individual capability. The successful application of detector technologies largely depends on proper device selection. Many factors impact detector selection, such as data type, data accuracy, ease of installation, cost and reliability. ILD’s are flexible to satisfy different variety of applications, but installation requires pavement disturb.

I wish to thank several of my students and staff of NPTEL for their contribution in this lecture. Specially, I wish to thank my student K. B. Raghuram for his assistance in developing the lecture note, and my staff Ms. Reeba in typesetting the materials. I also appreciate your constructive feedback which may be sent to tvm@civil.iitb.ac.in

Prof. Tom V. Mathew

Department of Civil Engineering

Indian Institute of Technology Bombay, India

_________________________________________________________________________

Thursday 31 August 2023 12:12:27 AM IST